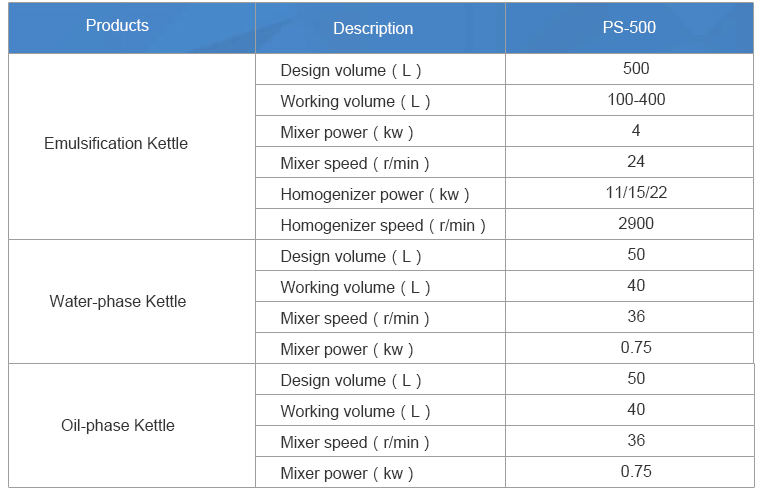

Technical Paramende

Chigadzirwa Chigadzirwa

Iyo emulsification sisitimu yakagadzirirwa kugadzirwa kwekusimudzira emulsion kune akasiyana maindasitiri. Kune mashanu modhi modhi anotangira pa5L kusvika 1000L, kusanganisira yekuyedza, yepakati uye yakakura saizi.

Iyo sisitimu yakapusa mukugadzira uye nyore kushandisa, uye muchina wese unowedzera-kuchengetedza nzvimbo maererano nehurefu dhizaini. Yepamberi yekusanganisa michina inovimbisa yunifomu mhando yeakapedza chigadzirwa Iyo inochinjika uye inogona kushandiswa nemhando dzakasiyana-siyana dzekupepetera senge vhoriyamu, kudziyisa bhachi / kutonhora, zvivharo zvakawanda-zvakavhurika, masampling dhizaini, nezvimwe. Inoita iyo SP system chishandiso chakanakira kugadzirisa zvinwiwa. Iyo inochinjika mukugadzira uye inogona kuve inoenderana maererano nezvinodiwa nemaindasitiri akasiyana. Inogona kushandiswa muemulsion uye mukugadzira mishonga mu cosmeceutical indasitiri, mukugadzirwa kwemayonnaise uye macondiment muindasitiri yezvikafu, mukugadzira emulsions, kusimudzira, pigments uye kupfeka muindasitiri yemakemikari, nezvimwe.

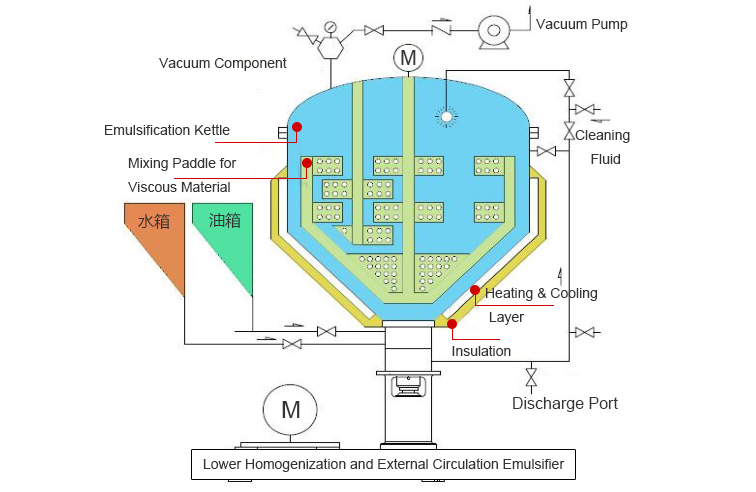

Maumbirwo uye Kushanda Kuyerera

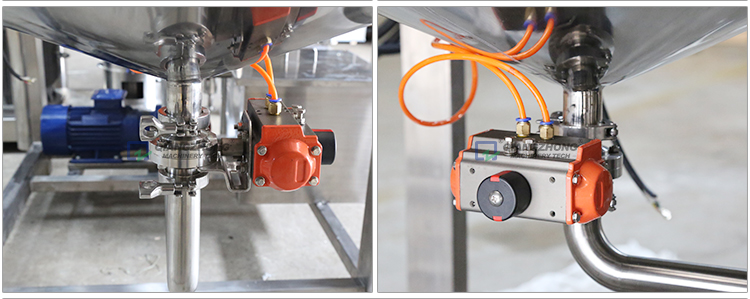

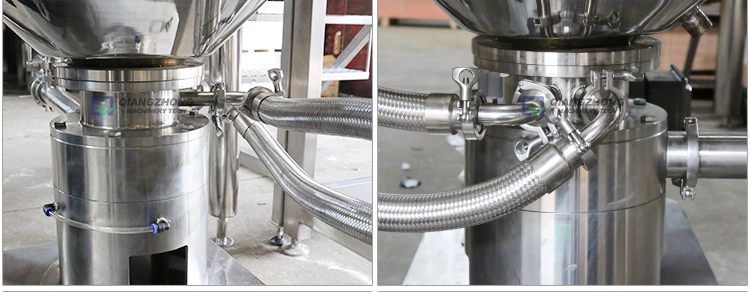

Iko kwekunze kutenderera homogenization system ndiyo musimboti weiyo system. Inobatanidza kufema, kutakura, kupararira, uye CIP online kuchenesa. Iyo mbiri-nhanho pombi dhizaini inobvumidza iyo homogenization system kupa kwete chete simba rekusanganisa izvo zvinhu, asi zvakare ine simba yekupomba kugona uye kugona kuendesa yakanyanya viscous zvinhu. Iyo inobvumidza iyo aqueous chikamu uye chikamu chemafuta kuve emulsified yakanangana muiyo homogenization system, uyezve ndokupombi kune iyo reactor yekushushikana, nekudaro ichidzivirira hurema hunokonzerwa neyakajairika maitiro.

Iyi isisitimu inoshanda kwazvo inobatanidza yakakwira kutenderera kuburitsa, kuenzana kwekugadzirwa kwezvinhu zvidimbu size uye nemhando yepamusoro emulsification. Solids uye zvinwiwa zvinogona kuwedzerwa zvakananga kune emulsification musoro uye nekukurumidza uye zvakakwana emulsified uye zvakapararira kudzivirira kusangana. MuCIP yekuchenesa maitiro, iyo sisitimu inogona kushandiswa sepombi yekuchinjisa kuti ipe yakanyanya yekumanikidza yekuchenesa fluid yekushandura mabhora ekupfapfaidza.

- Iyo emulsification uye yekuparadzira zvikamu zvinowedzerwa zvakananga kumusoro unoshanda.

- Modular dhizaini yetayi tsvimbo iri nyore kugadziriswa nekukatanura.

- Kutenderera kwechinhu, kuchenesa CIP, hapana mamwe mapombi anodikanwa pakuburitswa.

- Sarudzo yemahara yekuti izvo zvinhu zvichapfuura nemu emulsification kamuri.

- Zvirinani kugadzirisa mhedzisiro, ipfupi kugadzira nguva.

Iyo yepakati emulsification sisitimu inogona kusanganiswa neakasiyana hoppers, prereatment reactors uye kuburitsa buffer matangi zvichienderana nezvinodiwa zvekugadzira. Zvinoenderana nechinhu ichi, akasiyana madhiri ekupisa uye anotonhora anogona kuwedzerwa. Kunyangwe iwo wekutenderera mutsetse unogona zvakananga kupfuudza chiutsi kupisa izvo zvinhu. Zvimwe zvinobudirira ndiko kuramba tichitsvaga.

Iyi sisitimu yemagetsi yekudzora yuniti inogona kugadziridzwa neyakareruka bhatani kutonga kana iyo PLC yekubata skrini system neresipi yekudzora, zvinoenderana nesarudzo yemutengi. Chinyorwa kana zvakazara otomatiki michina inowanikwawo pakukumbira.

Inofananidzwa nemhando imwechete yemidziyo kunze kwenyika, yedu otomatiki system haigone chete kusangana nezvinodiwa nemutengi (inogona kupa yakapusa system kuyedza), asi zvakare ine zvakanakira zvikuru maererano nemutengo, nguva yekuendesa uye neshure-yekutengesa sevhisi.

Chigadzirwa Showcase